PS-900

- The needle-bar turning mechanism helps achieve high-quality seams uniformly in every sewing direction

- Active tension for needle bar rotation 360°

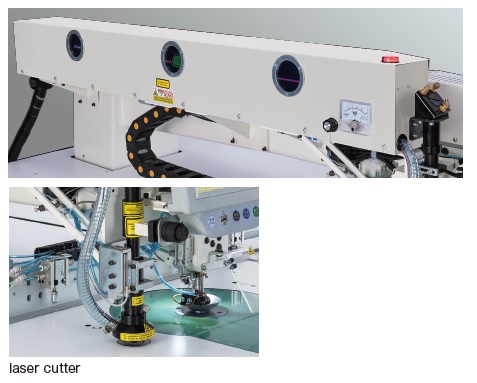

- Cloth trimmer specifications

- Intelligent Medium-Presser Foot

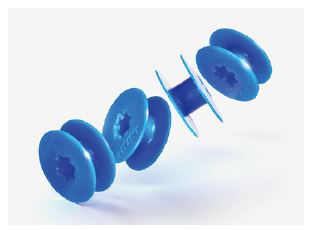

- The bobbin adopts a plastic bobbin

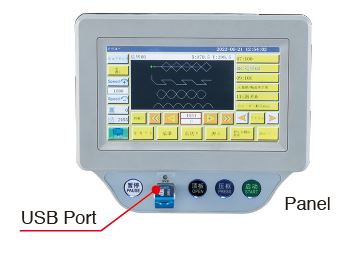

- Operation panel

Description

The needle-bar turning mechanism helps achieve high-quality seams uniformly in every sewing direction

JUKI’s unique synchronization technology controls the needle bar, hook and feed mechanism, thereby creating the most favorable seams. In case of continuous circumference sewing, the sewing machine constantly detects the direction of sewing. As a result, consistent-quality seams are produced regardless of the direction of sewing.

Active tension for needle bar rotation 360°

Market-prov active tension has been introduced to the needle thread tension controller.With the active tension, pinpoint changes in the needle thread tension during sewing are enabled. The needle thread tension, therefore, can be set in conjunction with the material thickness and can be corrected according to the direction of sewing on a stitch-by-stitch basis through the operation panel.

Basic performance

Cloth trimmer specifications

A laser cutter is available for the cloth trimmer specification. This laser cutter is suitable for soft materials such as knit fabrics.

-

Patterns are identified by means of RFID/Barcode reader to enable automatic reading of sewing data

Sewing patterns are automatically identified by means of RFID/Barcode reader to automatically call up the relevant sewing program, thereby starting sewing quickly.

-

The bobbin adopts a plastic bobbin

Since the plastic bobbin is lighter than aluminum and iron, the thread tension is stable at a high level.

●Plastic bobbin (10 pieces)

Parts No.40244784 -

Intelligent Medium-Presser Foot

It is possible to change the intermediate presser height at its lower dead point steplessly during sewing. This feature is particularly effective when sewing multi-layered portions of material. Since the material is stably held by the intermediate presser, sewing troubles such as stitch skipping and thread breakage are prevented.

-

Operation panel

The sewing pattern data format are supports DXF, AI, PLT, and DST. Sewing pattern data in these formats are widely used in many sewing plants. As a result, the operation panel is able to use the

customers’ existing sewing pattern data immediately. As many as 999 sewing patterns can be saved on the large-capacity memory of the operation panel. (Editing software is included with the accessory.)

Specification

| Model name | PS-900SB13090CKZ PS-900SB13090CKW |

PS-900SB13090ZKZ PS-900SB13090ZKW |

|---|---|---|

| Sewing area | 1,300 mm × 900 mm | |

| Max. sewing speed | 3,000 sti/min* | |

| Lubrication | Semi-dry | |

| Feeding type | Belt Drive | |

| Stitch length | 0.5 – 12.7 mm | |

| Hook | Full-rotary standard-capacity hook | |

| Cutter equipment | Laser | – |

| Lift / Stroke of intermediate presser |

Lifting amount: 20 mm / Stroke: Standard 4 mm | |

| Variable lower position of the intermediate presser |

0 – 9 mm | |

| Needle | DB × 1 #8 (7#~14#) | |

| Template recogniser | RFID: 13090CKZ Barcode: 13090CKW |

RFID: 13090ZKZ Barcode: 13090ZKW |

| Number of indentifiable patterns | 999 patterns | |

| Program input mode | USB | |

| Weight | 649 kg | 575 kg |

| Dimensions | 2,100mm (W) × 2,325mm (L) × 1,240mm (H) | |

Reviews

There are no reviews yet.