AB-1351 | Automatic 1-needle Belt-Loop Attaching Machine

AB-1351 | Automatic 1-needle Belt-Loop Attaching Machine

AB-1351 | Automatic 1-needle Belt-Loop Attaching Machine

Product features

-

Belt-loop folding mechanism which supports various belt-loop specifications (patent pending)

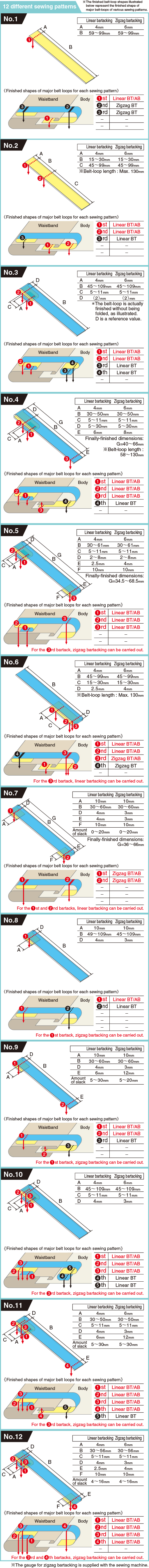

This is the world’s first automatic belt-loop attaching machine which can be used for seven different belt-loop attaching processes. The main mechanisms have been computerized to develop a belt-loop attaching machine which sews diversified belt-loop styles.

-

Improved productivity

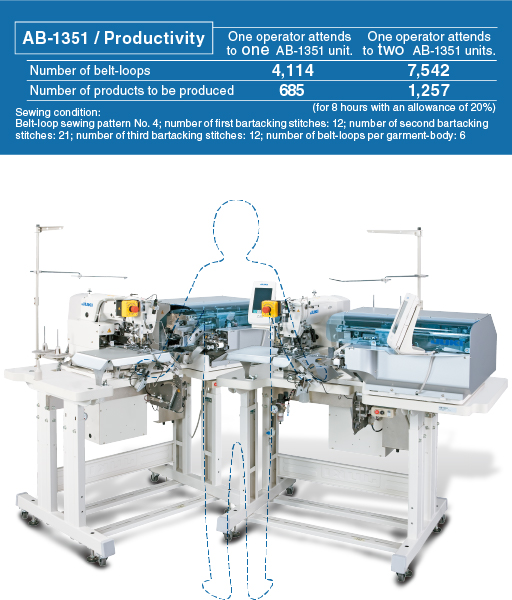

This machine not only reduces the time required for the belt-loop attaching process, but also achieves labor-saving, such as the elimination of the previous process (belt-loop cutting). Productivity can be dramatically increased when one operator attends to two AB-1351 units.

Productivity is dramatically increased when the operator attends to two AB-1351 units.

Two AB-1351 units can be operated by only one operator. In the case where two AB-1351 units are placed, as shown in the picture, the operator is able to operate them alternately to attach belt-loops on two different garment bodies, thereby substantially increasing productivity.

Specification

| Model name | AB-1351 | |||

|---|---|---|---|---|

| Machine head | LK-1961/ABH (Exclusive machine head based on the LK-1900A, Semi-dry-head) | |||

| Max. sewing speed | 2,500sti/min* | |||

| Lift of the work clamp foot | Max.14mm | |||

| Hook | Standard shuttle hook | |||

| Stored bartacking patterns (Stittches) | Linear bartacking (12, 15, 21, 28, 36, 41) / Zigzag bartacking (28, 36, 42, 56, 64) | |||

| Bartacking size | length-wise | 0~3.2mm (0″~1/8″)〈adjustable in increments of 0.1mm〉 | ||

| cross-wise | 6~23mm (15/16″~57/64″)〈adjustable in increments of 0.1mm〉 | |||

| Number of bartacking patterns that can be input | Max. 200 patterns, (Max. 20,000 stitches in total patterns) | |||

| Number of belt-Loop sewing patterns | 99 patterns | |||

| Number of cycle sewing patterns | Number of programs: 20 (30 different patterns can be set within one program.) | |||

| Needle | DP × 17 #14, 135 × 17 #90 | |||

| Thread | Spun 80Nm (recommend), Filament 80Nm (80Nm=#50) | |||

| Belt-loop width | 8~20mm (5/16″~25/32″) | |||

| Power requirement / Power consumption | Single-phase 220~240V / 280VA, 3-phase 200~220V / 250VA | |||

| Compressed air and air consumption | 0.5MPa (5kg/cm²), 10Nl/min | |||

| Total weight | 205.5kg | |||

| Dimensions | 1,200(W) × 850(D) × 1,210mm(H) | |||

| Height of the top face of the throat plate | Minimum: 930 mm (from the floor surface) | |||

| Needle thread breakage detecting device | Provided as standard (Sewing can be re-started in the case of thread breakage.) | |||

| Belt-loop multi-layered part detecting device | Provided as standard | |||

*sti/min stands for Stitches per Minute.

Reviews

There are no reviews yet.