AMB-289 | Computer-controlled, High-speed, Single-thread Chainstitch, Button-neck-wrapping Machine

AMB-289 | Computer-controlled, High-speed, Single-thread Chainstitch, Button-neck-wrapping Machine

AMB-289 | Computer-controlled, High-speed, Single-thread Chainstitch, Button-neck-wrapping Machine

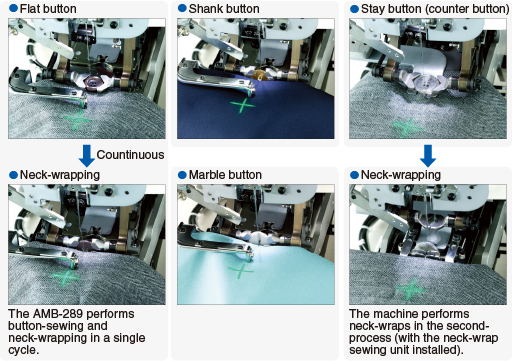

- This single machine can also sew flat buttons, shank buttons, marble buttons and stay buttons (counter buttons)

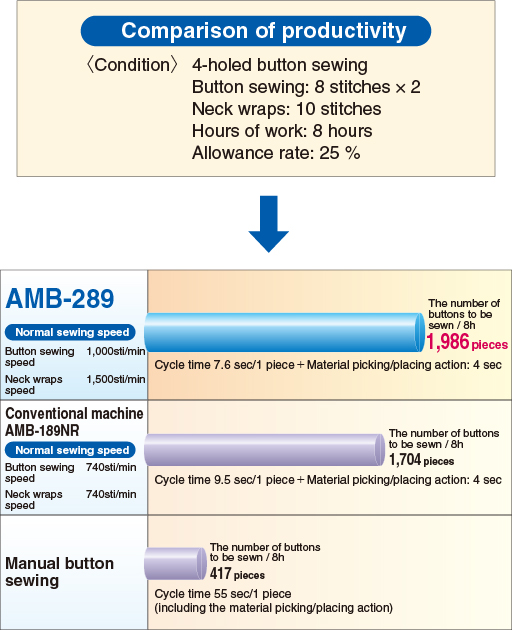

- The cycle time has been reduced to bolster productivity

- The color panel IP-420D provides excellent operability

- Cycle sewing

- Exclusive active tension (electronic thread tension control system)

https://www.juki.co.jp/industrial_e/products_e/apparel_e/automatic_e/detail.php?cd=AMB-289_E

Product features

-

This single machine can also sew flat buttons, shank buttons, marble buttons and stay buttons (counter buttons)

- The stay button (counter button) sewing capability is a vital addition to the impressive application range of the AMB-289.

- Sewing methods and sewing shapes can be easily reset on the operation panel.

- In combination with the independent-drive needle-throwing method, the adoption of the Y-feed on the body side and X-Y feed on the button-sewing side enables the AMB-289 to sew patterns with variable numbers of buttonholes (such as four-holed front buttons and two-holed stay buttons).

-

The cycle time has been reduced to bolster productivity

- The sewing speed has been enhanced to dramatically increase productivity.

- As compared with manual button sewing, the AMB-289 achieves productivity as high as 5 times.

-

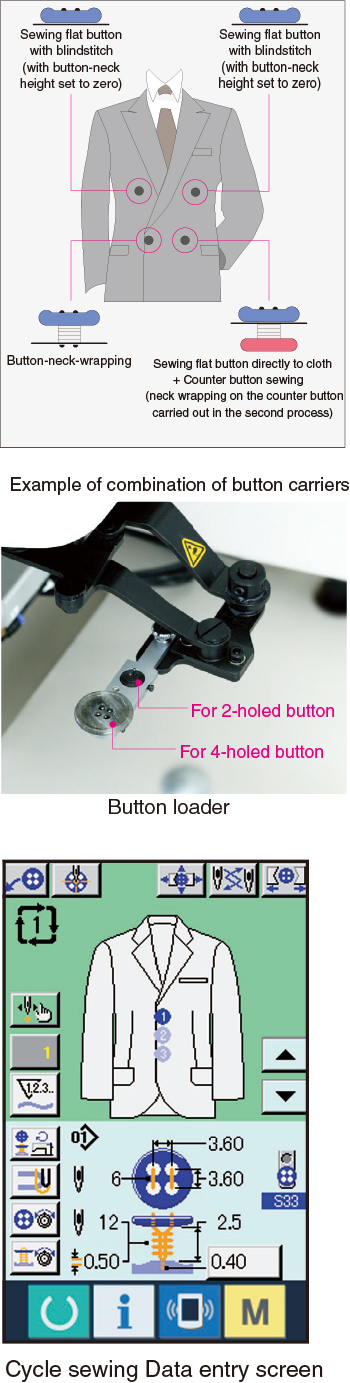

Cycle sewing

- The machine sews buttons on a double-breast suit, a garment that requires the sewing of different types of buttons, in a continuous manner.

- Cycle sewing data can be set/edited with the sewing item graphically displayed on the operation panel (the number of buttons, button sewing locations, and sewing order of buttons).

- The button loader can feed two types of buttons in a single sew ing cycle.

-

The color panel IP-420D provides excellent operability

- The operation panel is a touch-sensitive type LCD. The clear graphical displays make it much easier for the operator to set or modify sewing data.

- A CompactFlash™ card can be used to store and transfer sewing data. This makes it possible for sewing machines at one or more factories to share data. In addition to the CompactFlash TM, the machine is provided as standard with a USB connector. As a result, the use of a USB flash drive or card reader enables the storage and transmission of sewing data by means of various kinds of media (such as a floppy disk, SmartMedia, CompactFlash and SD card) to enable sewing using the same sewing data among sewing machines in a plant or among subcontract plants.

-

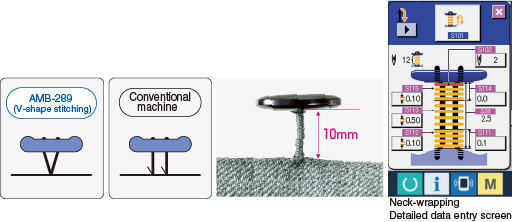

The AMB-289 promises upgraded-quality neck-wrapping

- The AMB-289 finishes four-holed buttons with a hand-stitched appearance (V-shape stitching) by fixing the tucking position at a preset location. This results in the sewing of a neat seam on the wrong side of the garment and neck-wrap knots at a single location. Seam quality is further enhanced as a result.

- The neck-wrap data can be finely adjusted via the entry screen of the operation panel to enhance the sewing quality. The distribution of neck wraps on the upper and lower parts of the button neck, a crucial point in determining the quality of neck-wrapping, can be adjusted to prevent buttons and button necks from becoming unstable and tilting.

- The neck-wrapping height can be adjusted by up to 10mm.

-

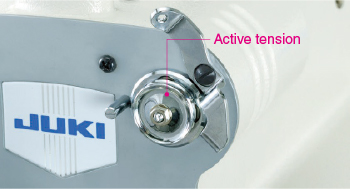

Exclusive active tension (electronic thread tension control system)

- The exclusive active tension system for AMB289 further improves responsiveness and allows delicate tension setting when the user changes fabrics.

- Thread tensions for button sewing and neck wrapping can be separately set on the operation panel.

- The machine stores sewing conditions in memory on a pattern-by-pattern basis. Required sewing conditions can be exactly reproduced for every pattern.

Related products

Leave A Review

Be the first to review “AMB-289 | Computer-controlled, High-speed, Single-thread Chainstitch, Button-neck-wrapping Machine” Cancel reply

Reviews

There are no reviews yet.