MOL-254 | Automatic 2-needle Belt-Loop Attaching Machine

MOL-254 | Automatic 2-needle Belt-Loop Attaching Machine

MOL-254 | Automatic 2-needle Belt-Loop Attaching Machine

Product features

-

The number of stitches and size of bartacking

The number of stitches to sew a belt-loop can be switched between; 28-, 36- and 42-stitches, and the bartacking size can be easily changed through the operating panel. What’s more, the user can create his/her own original sewing patterns in addition to the standard ones using JUKI’s PGM-20 programming software developed for computer-controlled sewing machines.

-

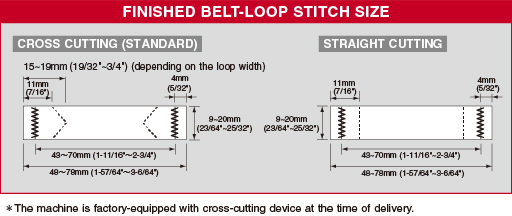

The changeover of cutting method between cross cutting and straight cutting

The applicable loop width for the cross-cutting device is increased. In this model, both the cross-cutting device and the straight-cutting device can now cut loop up to 20mm width.

-

The machine time is 1.2 seconds per belt-loop (with 28 stitches)

The new machine head specifically developed for belt-loop attaching machines runs at a maximum sewing speed of 2,500rpm and is equipped with a direct-drive system that improves start up performance and shortens sewing time. The belt-loop feeding device is now provided with a halfway standby capability for subsequent belt-loops, and its faster belt-loop supply action shortens the time required for supplying belt-loops and helps speed up the machine time to 1.2 seconds per belt-loop (with 28 stitches).

-

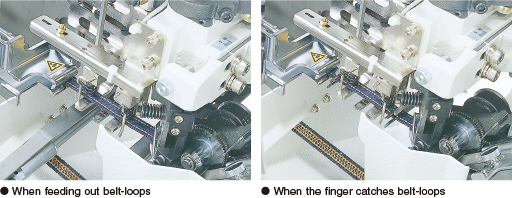

With the improved consistency in belt-loop supply action and re-try capability, the machine down time is substantially reduced

Belt-loops are fed out by the conventional gear-roller feeding mechanism and also drawn out by the new drawing mechanism on the clamp device. Supported by these two mechanisms, the folding fork catches “curled” or “creased” belt-loops every time and supplies them to the head. In addition, the sensor of the clamp device detects the presence/absence of belt-loops. If it detects a faulty belt-loop feed, the clamp device automatically repeats the clamping action. Since the operator doesn’t have to operate the set-back switch, less time is lost.

Specification

| Model name | MOL-254 |

|---|---|

| Machine head | Computer-controlled, 2-needle, lockstitch bartacking machine |

| Max. sewing speed | 2,500sti/min* |

| Thread take up | Link type |

| Needle bar stroke | 45.7mm |

| Thread | Spun thread, cotton thread #50~#30, B33~B46, Nm=120/3~60/3 |

| Needle (at the time of delivery) | DP×17 (#21) #19~#21 |

| Hook | Horizontal-axis 1.8 fold-capacity shuttle hook |

| Lift of the presser foot | 21mm |

| Number of stitches | 28, 36, 42 (selectable on the operating panel) |

| Needle gauge | 43~70mm (1-11/16″~2-3/4″) |

| Bartacking length | 7~22mm (9/32″~55/64″) ‹adjustable in increments of 0.1mm› |

| Bartacking width | 1~3.2mm (3/64″~1/8″) ‹adjustable in increments of 0.1mm› |

| Number of pieces of bartacking data that can be stored in memory | 9 (99 patterns if optional EP-ROM is added) |

| Belt-loop width | 9~20mm (23/64″~25/32″) |

| Finished length of belt-loop | 48~78mm (1-57/64″~3-5/64″) |

| Machine time | 1.2 sec./belt-loop (28 stitch) |

| Positioning of the front hook | Driven by motor (the distance between the hook can be established in increments of 0.01mm) |

| Bobbin winder | Electric type (provided as standard) |

| Lubrication | Centralized oil wick lubrication (machine head) |

| Lubricating oil | JUKI New Defrix Oil No.2 (equivalent to ISO VG32) |

| Power requirement and power consumption | Single-phase, 3-phase 200~240V/350VA |

| Compressed air and air consumption | 0.5MPa (5kgf/cm²), 32Nl/min |

| Total weight | 230kg |

| Dimensions | 1,200mm (W)×800mm (D)×1,350mm (H: in its lowest end) |

| Height of the top surface of the throat plate as from the floor surface | 920~1,250mm (provided with the adjustable stand capability) |

*”sti/min” stands for “Stitches per Minute.”

Reviews

There are no reviews yet.