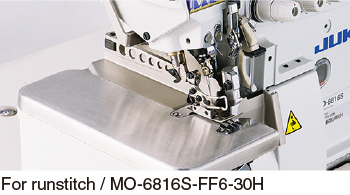

Juki MO-6800S Series High-speed Overlock / Safety Stitch Machine

This advanced overlock / safety stitch machine is easier to use and promises superior cost effectiveness.

The MO-6800S Series responds to various kinds of sewing materials and processes, producing delicate and beautiful soft-to-the-touch seams while further reducing operating noise as well as increasing durability. This advanced overlock / safety stitch machine is easier to use and promises superior cost-effectiveness.

Description

The machine achieves beautifully finished seams of improved quality even when run at a high speed

The machine is widely applicable to the sewing of light- to heavy-weight materials. Since the machine is provided with a needle thread take-up mechanism and a looper thread take-up lever, it ensures high-quality, well-tensed and soft seams with a beautiful texture which flexibly correspond to the elasticity of the materials even when run at speeds as high as 7,000 sti/min. In addition, the machine has a wider and brighter needle entry and provides improved responsiveness to the materials, thereby helping the operator use the machine more easily. The optimally-balanced design of the machine reduces both operating noise and vibration, contributing to more comfortable sewing work.

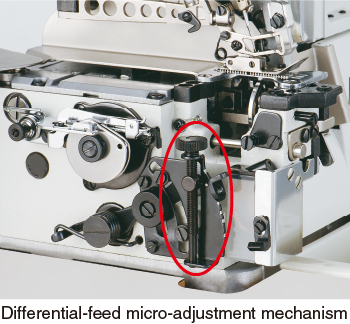

The machine is provided with functions which contribute to easier operation

The differential-feed micro-adjustment mechanism, external increasing of the differential feed ratio and the main feed dog height can all be adjustable on the front face of the sewing machine with a screwdriver. The machine is provided as standard with functions which enable easy and best-suited adjustments according to the material to be used.

Specification

| Model name | MO-6804S | MO-6814S | MO-6816S | MO-6843S |

|---|---|---|---|---|

| Stitch type | 1-needle overlock | 2-needle overlock | Safety stitching | 3-needle safety stitching |

| Stitch style in the U.S.A. | 504 | 514 | 516 | – |

| Max. sewing speed | 7,000sti/min* | |||

| Stitch length | 0.6~3.8 (4.5)mm | |||

| Needle gauge (mm) | – | 2.0 | 3.0, 5.0 | 3.0+2.0, 5.0+2.0 |

| Overedging width (mm) | 1.5, 4.0 | 2.0, 3.0, 4.0 | 4.0, 5.0, 6.0 | 3.0 |

| Differential feed ratio | For gathering 1:2 (Max. 1:4), For stretching 1:0.7 (Max. 1:0.6) | |||

| Needle bar stroke | 24.5mm (60H:27.0mm) | |||

| Inclination angle of the needle | 20° | |||

| Needle bar bushing | Lower bushing method | |||

| Needle | DC×27 (excluding some subclass model) | |||

| Max. lift of the presser foot | 7mm (excluding some subclass model) | |||

| Max. presser foot pressure | 63.7N (6.5kgf) | |||

| Stitch adjusting method | By push-button | |||

| Differential-feed adjusting method | By lever (with micro-adjustment) | |||

| Weight of the machine head | 27kg | |||

| Lubrication | Automatic | |||

| Lubricating oil | JUKI Machine Oil 18 (equivalent to ISO VG18) | |||

| Needle cooler | Provided as standard | |||

| Needle thread heat remover | Provided as standard | |||

| Micro-lifter | Option | |||

*”sti/min” stands for “Stitches per Minute.”

Reviews

There are no reviews yet.