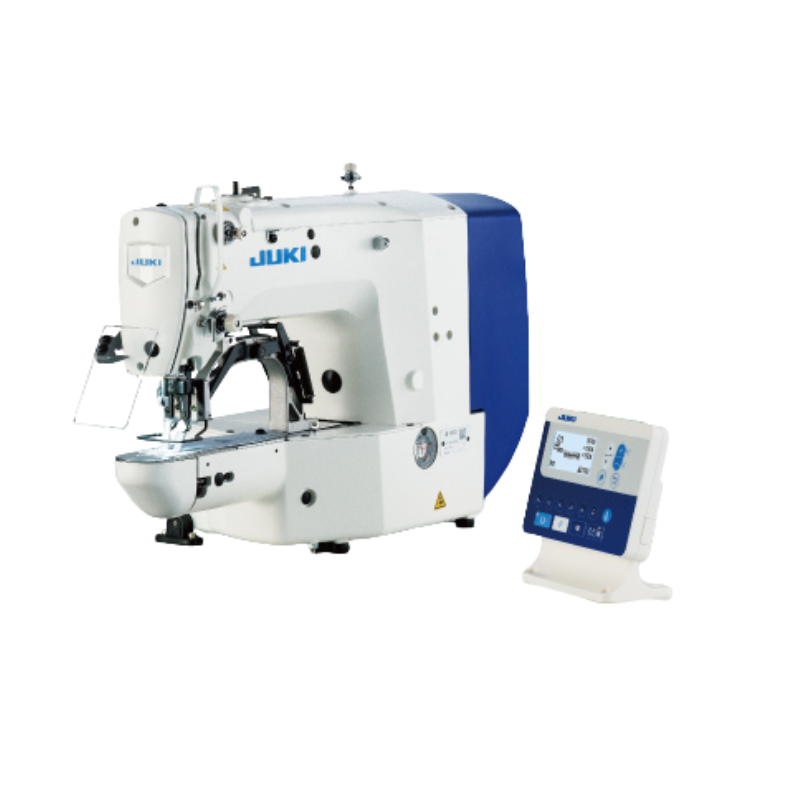

Juki LK-1900BN Series, Computer-controlled, High-speed, Bartacking Sewing System

Inspire the Knowledge in Sewing Adjustment.

Epoch-making Sewing Systems in history.

Digital sewing system proposes the production process added with a computerized new value to all the people who engage in production.

Description

High-Speed Performance and Precision Control

The Juki LK-1900BN Bartacking Sewing System delivers fast, precise, and consistent bartack stitching for all fabric types. It supports continuous high-volume production while maintaining stable operation. The computer-controlled system executes patterns accurately, reducing errors and ensuring uniform stitching. Its powerful motor provides smooth motion and strong needle penetration. Operators can produce clean and reliable bartacks consistently, improving output quality. The durable design ensures long-term performance under demanding conditions. Factories benefit from faster production cycles and reduced downtime. This machine guarantees a reliable workflow and consistent product quality for tailoring, garment factories, and industrial applications.

Machine is mounted with inbuilt NFC (Near Field Communication) and communication devices capable of a 2-way data transmission

Data on sewing machine adjustments made according to the product to be sewn can be transferred to a commercially- available Android tablet in contactless mode. This enables quick check for uniform settings as well as confirmation of conditions of sewing machines in a sewing line, thereby facilitating setup changes. The operation panel is also provided as standard with a USB port. Data management and software update can be carried out with ease using a USB thumb drive. Data items of sewing can be numerically managed to ensure “stable quality” and “reduction in time required for setup changes”. Quantified sewing data can be externally taken from the sewing machine using an Android tablet or USB thumb drive. *Android OS Version 6.0 is recommended to use JUKI Smart APP. (Operation is confirmed with respect to Versions 5.0 and later.) Contact JUKI distributor in your area for how to use the application software.

Bird’s nest preventing / Shorter-thread remaining functions (LK-1900BNB)

Thanks to the Bird’s nest preventing / shorter-thread remaining functions, manual thread-nipping is no longer required and gives soft and smooth feeling on the bartaking sections where directly contact skin such as brassieres and tank tops.

The sewing machine eliminates so-called “bird’s nests” (thread tangling in on the wrong side of the material at the beginning of sewing).

The thread is retained at the beginning of sewing and any excess thread is trimmed during sewing. As a result, the length of thread sewn in the seam is shortened, thereby achieving high-quality sewing performance while preventing thread from tangling in on the wrong side “of the material.”

The length of thread remaining on the material at the end of sewing has been reduced to 2 mm or less.*

The newly-developed shorter-thread remaining mechanism trims the thread shorter after the regular thread trimming operation. Additionally, thread waste produced by thread trimming is withdrawn by suction. Thanks to this mechanism, the trouble of manual thread nipping is avoided. * Use #60-80 (TEX22-30) polyester spun thread

Specifications

| Model name | LK-1900BN-SS | LK-1900BN-HS | LK-1900BN-FS | LK-1900BN-MS | LK-1900BN-WS |

| Application | Standard | For heavy-weight materials | For foundation | For knits and knitted materials | With large hook for heavy-weight materials |

| Max. sewing speed | 3,200sti/min* | 2,700sti/min* | |||

| Sewing area | 30mm (L) × 40mm (W) | ||||

| Stitch length | 0.1~10mm (0.1mm step) | ||||

| Needle bar stroke | 41.2mm | ||||

| Lift of the work clamp foot | Standard 14mm (17mm when the reverse-rotation needle-up function) | ||||

| Auto-lifter | Provided as standard (stepping motor type) | ||||

| Needle thread tension | Active tension (electronic thread tension control system) | ||||

| Needle (at the time of delivery) | DP×5 (#14) | DP×17 (#21) | DP×5 (#11) | DP×5 (#11) | DP×17 (#21) |

| Number of stitches | Max. 20,000 stitches | ||||

| Number of standard patterns | 51 patterns | ||||

| Number of data that can be input | 200 patterns (for up to 150 patterns, sewing data can be added.) | ||||

| Enlarging/Reducing facility | 20~200% (1% step), Pattern enlargement/reduction can be done by increasing/decreasing the stitch length | ||||

| Memory method | Internal-organs memory | ||||

| Bobbin thread counter | Provided as standard (up/down method) | ||||

| Lubrication | Hook: minute-quantity lubrication | ||||

| Hook: minute-quantity lubrication | JUKI New Defrix Oil No.2 (equivalent to ISO VG32) | ||||

| Sewing machine motor | 450W compact AC servomotor (direct-drive system) | ||||

| Power consumption | 250VA | ||||

| Weight | Machine head (include motor) 42kg, Control box 5.6kg | ||||