Juki LBH-1790S Computer-Controlled High-Speed Buttonholing Machine

JUKI Simple Series sewing machine LBH-1790S has been designed to have simplified and narrowed down capabilities that are essentially required to produce JUKI’s established seam quality.

Description

This machine supports consistent stitching for uniforms, fashion wear, and industrial apparel.

Its advanced control system ensures perfect buttonhole formation on every cycle.

Manufacturers achieve faster output while maintaining superior stitch quality.

The machine supports diverse fabric types from light cotton to heavy denim.

Production teams benefit from reliable operation during extended working shifts.

The intelligent design minimizes setup time and maximizes daily productivity.

Factories improve overall workflow efficiency using this dependable solution.

JUKI designed the Simple Series sewing machine LBH-1790S with simplified and carefully selected functions that deliver JUKI’s established seam quality.

In addition, it supports the operator with the voice guidance system to improve work efficiency.

Product features

Voice guidance for the operator

This sewing machine is provided as standard with the voice-guidance system with

clock function.

The system uses voice guidance for production support by informing operators about produced quantities, work progress, and sewing machine operation rates after initial setup.

Operators easily enter function settings, including pattern numbers and needle thread tension, through the operation panel.

They also quickly change the distance between buttonholes using the enlargement and reduction function.

The operation panel includes a USB port as standard.

Operators manage sewing data and perform software updates easily through the USB port.

Basic performance

-

Main functions driven electrically

The machine adopts an electric-driven mechanism for the work clamp foot lifter, needle and bobbin thread trimmers, work clamp foot pressure regulator, cloth trimming knife, and thread tension controllers, ensuring stable sewing, beautiful seams, and reduced operating noise.

-

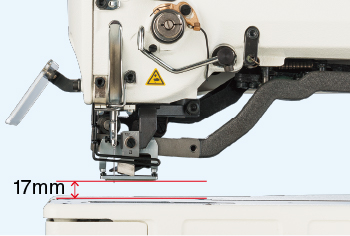

Work clamp foot lifting height

You can set the work clamp foot lifting height as desired. The reverse-rotation needle-up function allows you to lift the work clamp foot up to 17 mm.

-

Active tension

(electronic thread tension control mechanism)-

Operators set the needle thread tension separately for the parallel section and the bartacking section of the buttonhole seam according to sewing conditions such as thread, material, and sewing speed.

They store these setting data in memory. -

The machine changes the needle thread tension automatically between the parallel and bartacking sections, producing a beautifully finished buttonhole stitch shape.

-

Operators also set the needle thread tension individually at the beginning and end of sewing.

This setting prevents thread slip at the start of sewing and prevents seam unraveling after completion.

-

-

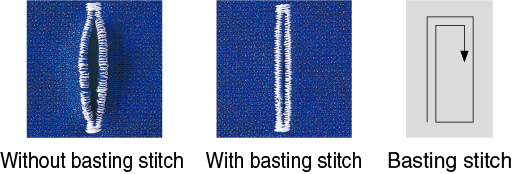

Basting stitch on elastic materials

The basting stitch is effective on elastic materials such as knits.

Basting stitch : Since the needle thread is tucked in without fail, it will never jut out of the buttonhole seams. Basting stitch can be sewn by nine rounds.

-

Multiple-times knife dropping

JUKI’s unique multiple-times knife dropping function eliminates the need for knife replacement when operators change the buttonholing size. During small-lot production, operators frequently change sewing sizes and cycle patterns with different dimensions.

In these situations, the system automatically sets the number of cloth trimming knife drops according to the selected buttonholing size. -

Easy changeover of sewing settings

Changeover between purl stitching and whip stitching and between single stitching and double stitching can be carried out with ease.

-

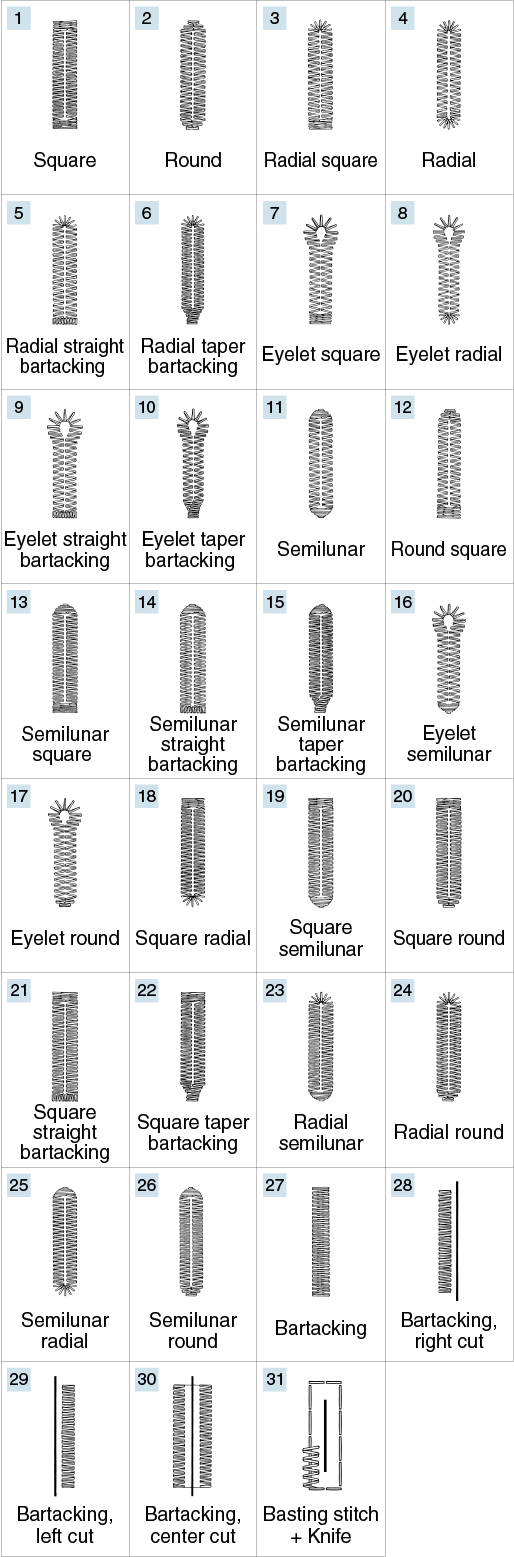

As many as 31 different buttonholing shapes are provided as standard

As may as 99 different sewing patterns can be stored in memory.

The sewing patterns that are stored in memory can be selected as desired through the operation panel.

Specifications

| Model name | LBH-1790S |

| Application | Standard |

| Lubrication | Semi-dry head (Hook : minute-quantity lubrication) |

| Max. sewing speed | 4,200sti/min (at the time of delivery : 3,600sti/min)* |

| Size of cloth cutting knife | 6.4~31.8mm (1/4″~1-1/4″) |

| Buttonhole length | Max. 41mm |

| Needle thread tension | Active tension (solenoid) |

| Needle (at the time of delivery) | DP×5 (#11J) #11J~#14J |

| Lift of the work clamp | 14mm (17mm when the reverse-rotation needle-up function is used) |

| Auto-lifter | Provided as standard (stepping motor type) |

| Needle throwing system | Stepping motor |

| Cloth feeding system | Stepping motor |

| Cloth cutting knife system | Motor-driven clamp system |

| Number of standard patterns | 31 patterns |

| Number of patterns that can be input | Max. 99 patterns |

| Machine head drive system | Compact AC servomotor (direct-drive system) |

| Power requirement / Power consumption |

Single-phase 200~240V / 370VA |

| Weight | Machine head (include motor) 55kg, Control box 5.5kg |

Reviews

There are no reviews yet.