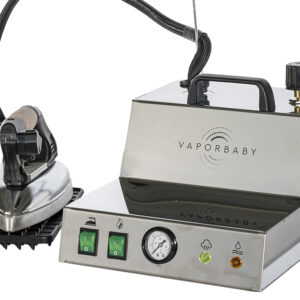

Primula Ecovaper Front Industrial Electric Steam Generator

Industrial electric steam generator for continuous operation

Available in 6 models based on the different power supplies (from 2.5 to 6 kW).

Electronically controlled by a PCB and with a water level control system by one electrode. Different connections for one, two or three steam irons. Suitable for the garment industry, dry cleaners, tailor shops and ateliers.

Description

Industrial Steam Solution for Professional Garment Production

The Primula Ecovapor Front Steam Generator is designed for continuous industrial steam production. It supports garment factories, dry cleaners, tailoring shops, and professional ateliers. The generator is available in six models with power options from 2.5 to 6 kilowatts. This variety allows businesses to select ideal performance capacity. The system supports connections for one, two, or three steam irons. This design improves productivity across multiple workstations. Electronic PCB control ensures stable operation and accurate steam delivery. The single-electrode water level control system increases efficiency and reliability. This generator delivers consistent performance under heavy workloads. It supports uninterrupted production cycles with excellent stability.

Advanced Construction and Safety Engineering

The Primula Ecovapor Front Steam Generator features a cylindrical steel boiler with 8.5-liter capacity and 6.5-millimeter thickness. Water drops glide smoothly to the boiler bottom. Inside and outside welding prevents oxidation and extends service life. The double steam outlet provides dry steam for two irons. The copper tube water inlet improves water flow and durability. An external safety valve follows strict TÜV safety standards. A 20-liter external water tank reduces refill interruptions. Heavy-duty wheels allow easy movement and fast servicing. Every component focuses on durability, safety, and long-term reliability.

Operational Advantages and Professional Efficiency

The Primula Ecovapor Front Steam Generator operates through a single main switch. The built-in electric water pump resists pressure and includes thermal protection. Electrical circuits use silicon wires for improved heat resistance. All electrical parts connect with grounding for enhanced operator safety. A blocking system on the water outlet valve protects against accidental burns. These advantages ensure safe and efficient daily operation. The generator maintains consistent output during extended usage. It reduces downtime and improves workflow efficiency. Professionals trust this system for continuous industrial performance. This generator represents innovation, reliability, and modern steam technology.

Additional information

| Steel boiler | 8.5 L |

|---|---|

| Operating pressure | 3.5 bar or 4.5 bar (after request) |

| Test pressure | 6 bar |