Juki DDL-5550N 1-Needle Lockstitch Machine

Juki DDL-5550N-7 and DDL-5550N

1-needle, Lockstitch Machine

DDL-5550N-7(with automatic thread trimmer)

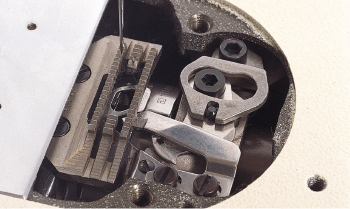

The thread take-up mechanism, feed mechanism, thread paths and hook have been further improved to enhance responsiveness to material changes and to ensure consistent stitch quality.

Description

High-Speed Industrial Performance

The Juki DDL-5550N lockstitch machine is designed for factories, tailoring units, and professional workshops demanding reliable daily production.

This machine delivers smooth, accurate stitching even during long working hours.

Its high-speed operation increases productivity while maintaining excellent stitch consistency.

Operators enjoy stable performance with minimal vibration and reduced operator fatigue.

The machine handles lightweight to medium fabrics with ease and confidence.

Its strong mechanical structure ensures consistent output across different sewing tasks.

Sure thread trimming mechanism

(DDL-5550N-7)

The machine comes with a thread trimming mechanism that performs speedy and sure thread trimming to achieve highly efficient sewing work.

Higher lift of the presser foot

The ample lift of the presser foot makes it easier to set or remove materials or to sew overlapping sections.

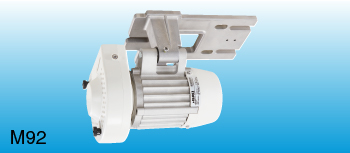

Newly developed control box SC-920/ Compact-size servomotor M92

JUKI has newly developed the SC-920C control box to resist voltage fluctuations, electrical noise, and vibration. This control box introduces an energy-saving mode for the first time in a sewing machine controller. It reduces power consumption during standby by approximately 25 percent compared to the SC-910N. JUKI also equips the DDL-5550N-7 with advanced energy-saving technologies, including the latest compact M92 servo motor. These upgrades improve environmental performance, reduce power usage, and significantly increase production efficiency.

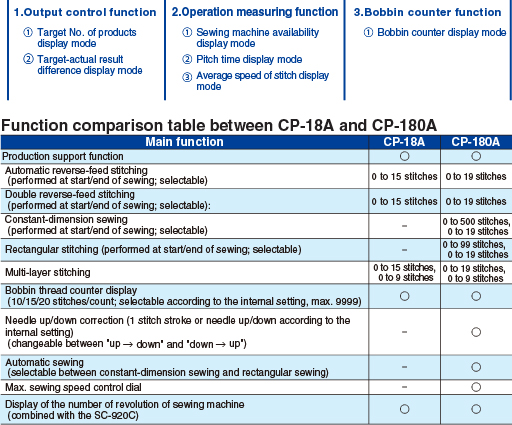

The operation panel CP-18A and CP-180A can be selected according to the process

Two different operation panels, the CP-18A and CP-180A are applicable to the DDL-5550N-7. Both operation panels are provided with the production support function.

The production support function actually consists of three different functions (six different modes).

Specification

| Model name | DDL-5550N-7 | DDL-5550NA-7 | DDL-5550NH-7 |

|---|---|---|---|

| Application | For medium-weight materials | For light-weight materials | For heavy-weight materials |

| Max. sewing speed | 5,000sti/min* | 4,000sti/min* | |

| Max. stitch length | 4mm | 5mm | |

| Needle bar stroke | 30.7mm | 29mm | 35mm |

| Lift of the presser foot | By hand: 5.5mm, By knee: 13mm | By hand: 4mm, By knee: 9mm | By hand: 5.5mm, By knee: 13mm |

| Needle (at the time of delivery) |

DB×1 (#14) For JE: 134 (Nm75) |

DA×1 (#9) For JE: 134 (Nm65) |

DB×1 (#21) For JE: 134 (Nm130) |

| Hook | Automatic-lubricating full-rotary hook | ||

| Lubrication | Automatic | ||

| Lubricating oil | JUKI New Defrix Oil No.1 (equivalent to ISO VG7) | ||

| Automatic reverse feed function | Provided as standard | ||

| Power reuirement | Single-phase 100~120V, 200~240V, 3-phase 200~240V | ||

| Power consumption | 650VA | ||

| Total weight | 81kg | ||

| Model name | DDL-5550N | DDL-5550NA | DDL-5550NH | |

|---|---|---|---|---|

| Application | For medium-weight materials | For light-weight materials | For heavy-weight materials | |

| Max. sewing speed | 5,500sti/min* | 4,000sti/min* | ||

| Max. stitch length | 5mm | 4mm | 5mm | |

| Needle bar stroke | 30.7mm | 29mm | 35mm | |

| Lift of the presser foot | By hand: 5.5mm, By knee: 13mm | By hand: 4mm, By knee: 9mm | By hand: 5.5mm, By knee: 13mm | |

| Needle (at the time of delivery) |

DB×1 (#14) For JE: 134 (Nm75) |

DA×1 (#9) For JE: 134 (Nm65) |

DB×1 (#21) For JE: 134 (Nm130) |

|

| Hook | Automatic-lubricating full-rotary hook | |||

| Lubrication | Automatic | |||

| Lubricating oil | JUKI New Defrix Oil No.1 (equivalent to ISO VG7) | |||

*“sti min”stands for“Stitches per Minute”

Reviews

There are no reviews yet.