Juki DLU-5494N-7/ IT-100A

1-needle, Bottom and Variable Top-feed, Lockstitch Machine with Automatic Thread Trimmer and Program Shirring Control Device

With its digital control, the machine achieves high-quality shirring with consistency.

Description

The machine enables even inexperienced operators to perform shirring operations smoothly and easily

The digital-controlled shirring mechanism allows even inexperienced operators to carry out shirring operations skillfully, producing high-quality products with consistency.

While shirring, an operator can enter a program through the use of the teaching function, thereby duplicating a high-quality shirring operation performed program by a skilled operator.

The best seam quality is produced by low-tension sewing

Through a thoroughgoing study of the sewing mechanism to enhance the machine’s ability to respond flexibly to diversified kinds of materials, the DLU-5494N-7 is now able to perform low-tension sewing with even higher precision and quality. The machine produces beautifully finished seams with consistency while preventing sewing troubles such as puckering and uneven material feed.

Higher lift of the presser foot and upgraded operability

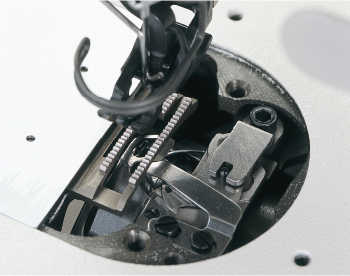

The lift of the presser foot is as high as 13mm. The top feed amount can be easily adjusted by operating the panel. The machine incorporates a built-in top-feed mechanism which simplifies the area around the presser foot, thus allowing the operator to easily place and handle a material on the machine. The machine can be operated as the operator wants.

The thread trimmer cuts threads with high to low thread counts without fail

Through the combined use of a moving knife and counter knife, the thread-trimming mechanism cuts thread with consistency. Any thread, ranging from high-to low-count thread, can be cut quickly without fail.

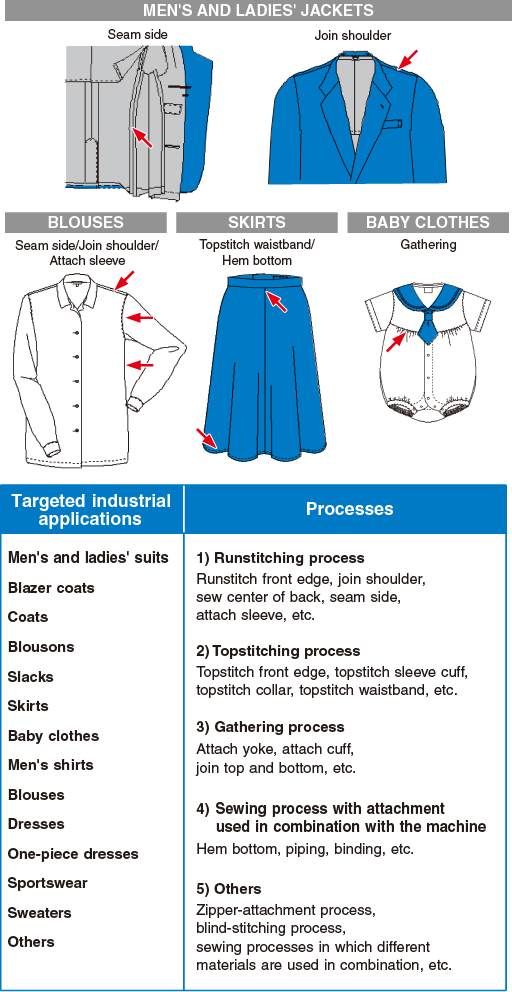

TARGETED INDUSTRIAL APPLICATIONS AND PROCESSES

The machine is ready to be used for broader applications, such as men’s wear, ladies’ wear, jackets and baby clothes, increasing facility efficiency.

-

Dramatically improved functions and performance

- The number of shirring programs has been increased to 16 different patterns. In addition, a maximum of 999 different patterns can be stored in the memory by the use of USB Memory in addition to the number of patterns stored in the main unit’s memory.

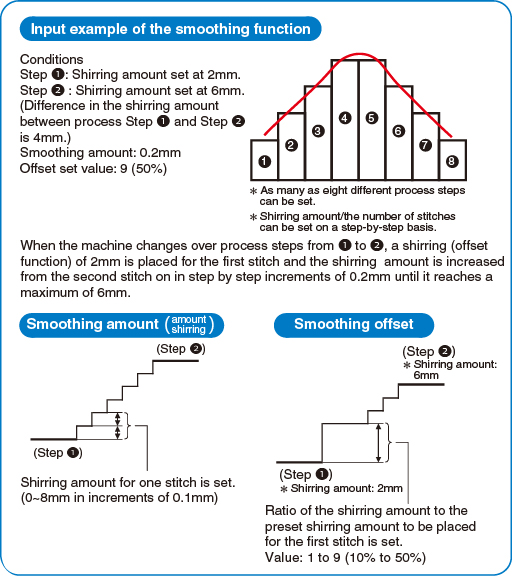

- The number of shirring process steps has been increased to a maximum of eight. The number of stitches and shirring amount can be preset for each step to allow the number of process steps to be added or deleted.

- The process steps and shirring amounts are displayed on the IT-100A panel to offer improved operability.

- By the use of the smoothing function, abrupt changes which take place when changing over the process steps can be reduced to achieve upgraded seam quality.

- Once the data on one sleeve is programmed, the data for the other sleeve is automatically programmed by means of the mirroring function.

- The machine has been provided with an alternating sewing function, which works in such a way that once the machine performs thread trimming after completion of the sewing of one sleeve, it automatically starts the sewing of the other sleeve (according to the mirrored data).

-

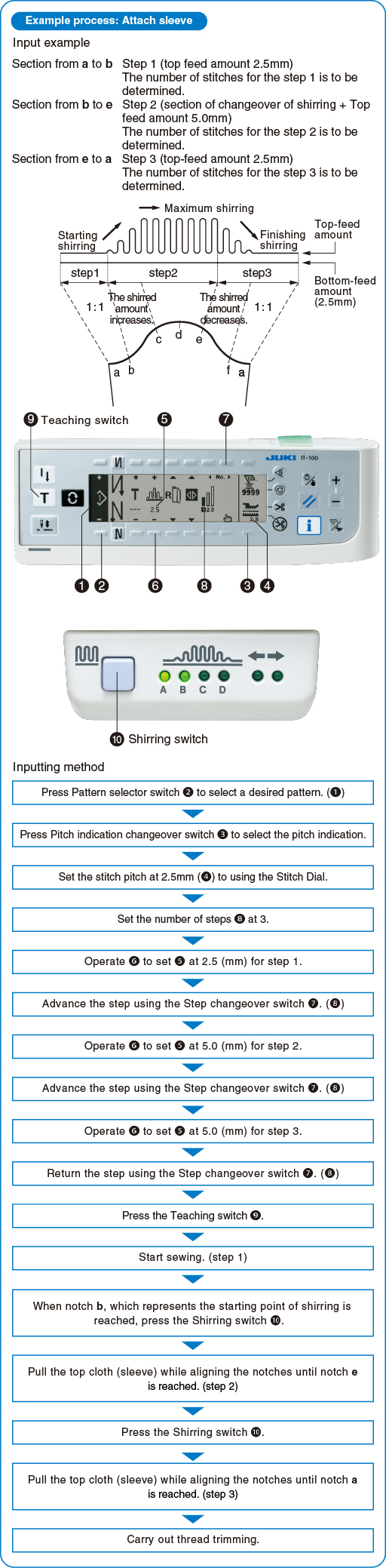

AN EXAMPLE OF INPUTTING A PROGRAM USING THE TEACHING FUNCTION

Teaching function: The function which enables setting the number of stitches using the number of stitches actually sewn.

This enables the quick and easy programming of data.

Specification

| Model name | DLU-5494N-7/ IT-100A | ||

|---|---|---|---|

| Max. sewing speed | 4,000sti/min (normal 3,500sti/min)* | ||

| Max. stitch length | 5mm (normal feed), 3mm (reverse feed) | ||

| Max. top-feed amount | 8mm (top-feed amount varies depending on the type of gauge) | ||

| Needle bar stroke | 30.7mm | ||

| Lift of the presser foot | By hand: 5.5mm, By knee: 13mm (max.) | ||

| Needle (at the time of delivery) |

DB×1 (#14), For JE: 134 (Nm75) | ||

| Hook | Automatic-lubricating full-rotary hook | ||

| Lubrication | Automatic | ||

| Lubricating oil | JUKI New Defrix Oil No.1 (equivalent to ISO VG7) | ||

| Automatic reverse feed function |

Provided as standard | ||

| Power requirement | Single-phase 100~120V, 200~240V, 3-phase 200~240V | ||

| Power consumption | Power rating 400VA | ||

| Total weight | 83kg | ||

*”sti/min” stands for “Stitches per Minute.”

PROGRAMMING DEVICE PERFORMANCE

| Function/Performance | SC-922 / IT-100A | |||

|---|---|---|---|---|

| Input mode | Manual | Possible | ||

| Teaching | Possible | |||

| Max. number of programs | Main unit’s | 16 patterns | ||

| USB Memory | Max. 999 patterns | |||

| Number of steps | Max. 8 steps | |||

| Addition and deletion of steps | Possible | |||

| Detailed data on steps stored in memory |

Shirring amount | 0~8.0mm (in increments of 0.1mm) | ||

| Number of stitches | 1~500 stitches (“0” means that the number of stitches is infinite.) | |||

| On-screen indication of stitch shape | Possible | |||

| Smoothing function | Possible / Effective between each of the two process steps. | |||

| Shirring amount for one stitch is set | Possible / 0~8.0mm (in increments of 0.1mm) | |||

| Ratio of the shirring amount to the preset shirring amount to be placed for the first stitch is set | Possible / Indications on the panel Value: 1~9 (10%~50%) | |||

| Mirroring function (inversion of data) | Possible | |||

| Alternating sewing | Possible | |||

Reviews

There are no reviews yet.