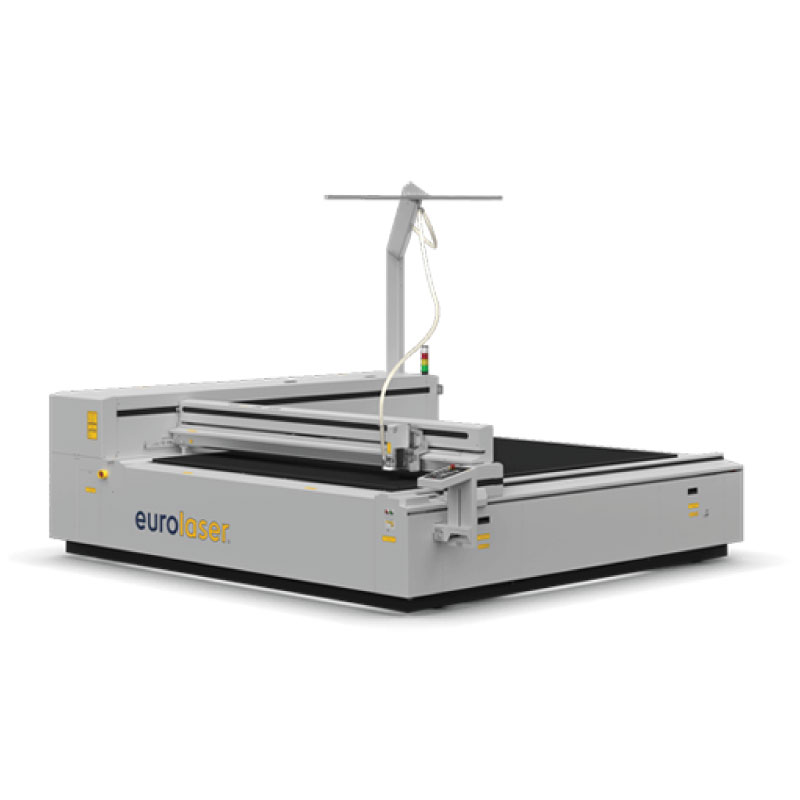

Eurolaser 2XL-3200 Laser Cutting Machine

Description

Overview

The laser cutter system 2XL-3200 is one of the biggest in the cutter series of eurolaser. The processing area is 2,740 x 3,200 mm (107.9″ x 126″), allowing to precisely cut and engrave large materials. The contactless laser cutting does not cause any bulges in the material and guarantees filigree cuts right from the beginning.

|

|

|

|

|

|

|

|

|

|

|

| Filigree Cuts | Clear cut edges | Engravings |

Which options do we offer?

| The modular design enables eurolaser systems to be specially configured to suit every requirement. We analyze your requirements and configure the laser system individually for you. The usage of eurolaser laser machines enables you to process a wide range of materials, such as cutting of plastics, foams, textiles, adhesive foils, wood, acrylic, composite materials and much more. | We are pleased to run a cutting test in our Application Center by using your individual material. Subsequently, you will receive a detailed test report in order to identify how your material was cut and engraved with our laser machines.

|

Automated processes for your laser machine – Higher productivity, more economical working – save time and money

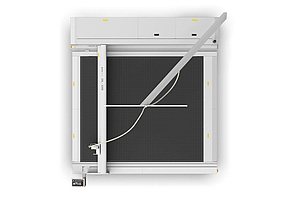

Remote OperationThe software-controlled division of the work area allows laser system operation on alternate sides. This enables production to be continued on the opposite side while removing and reloading material. |

|

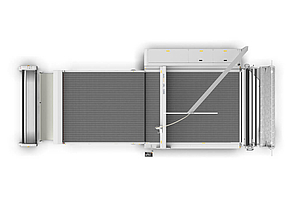

Conveyor SystemBy using this automatic material feed, textiles can be fed for laser cutting directly from the roll and routed after laser cutting directly to a table extension. With a high degree of connecting accuracy after a material feed cycle, sections, which for all practical purposes are endless, can be produced. The bale material is fed via an automatic feeding unit. An feeding system edge controller ensures accurate positioning of the material. There is even an option to add a winding unit to the Conveyor System. This is used for the even winding of previously processed textiles and this accordingly results in a completely automated cutting process. |

Optional extras

Customized options simplify everyday tasks and increase your possibilities

| |

POSITIONplus – Optical Recognition System Automatic camera detection enables printed materials to be cut out precisely along the printed outline. Even copying tolerances in the printed format can be compensated by software control. |

3 in 1 – Mechanical MachiningMechanical tool heads can be installed parallel to the laser, giving you the option to use tools such as milling cutters or knives. A valuable extension to your machining options with just one system technology. |

|

PICTUREplus – Raster Engraving UnitThis optional equipment allows machining of image files and production of both 2D-images and 3D-reliefs. Engraving is possible with a resolution of up to 1200 dpi and in 256 shades of grey. |

|

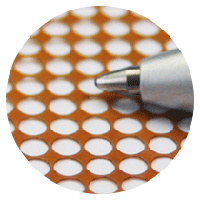

Ink Marker ModuleThe compressed air controlled jet system applies ink markings to the material. |

|

Exhaust and filter unitsSuction devices are selected to match your application and the table concept of your laser system. This guarantees complete emission extraction above and below the material. |

|

Cooling unitsThe high-quality energy efficient cooling units are fitted with electronic temperature controllers and monitoring systems, so that they always control ideal conditions for laser beam sources, in order to guarantee constant performance. |

Technical Specifications

| Working area (w x l) | 2,740 mm x 3,200 mm (107.8″ x 125.9″) |

| Dimensions (w x l x h) | 4,460 mm x 3,940 mm x 1,600 mm (175.5″ x 155.1″ x 62.9″) |

| Max. material width | 2,820 mm (111.0″) |

| Material clearance | 58 – 80 mm (according to material support) |

| Laser power | 60 to 650 watt |

| Laser source | CO2 |

| Speed | 1 – 1,414 mm/s (in steps of 1 mm) |

| Acceleration | max. 9.1 m/s² (358″/s²) |